Toyota anticipates an increase in battery recycling demand

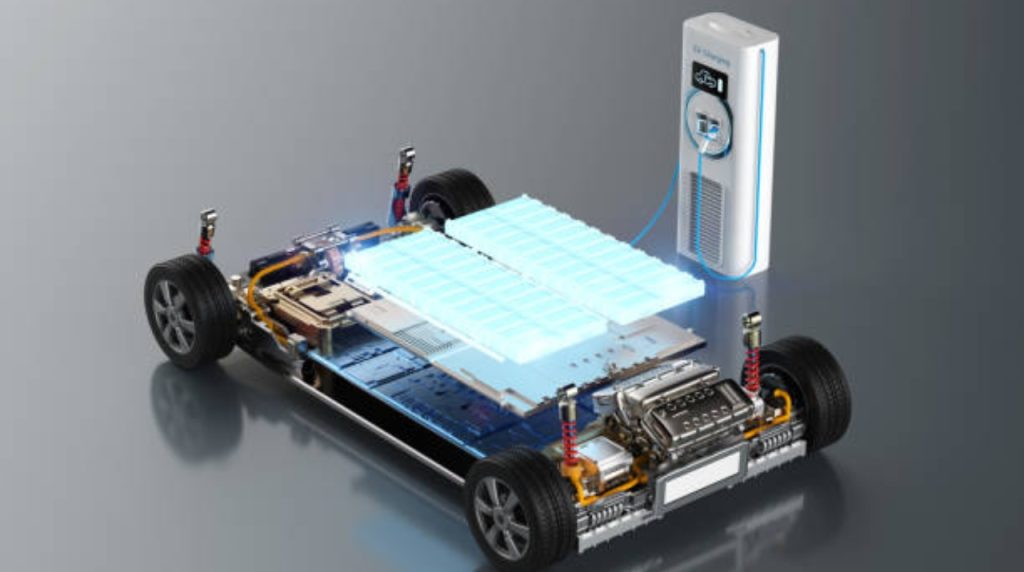

According to Toyota, an increase in battery recycling demands for the brand’s models is anticipated in the coming years, as more electrified vehicles, such as the first-generation Prius models introduced over two decades ago, reach the end of their lifespan.

Since a significant portion of Toyota’s retired electrified vehicle fleet is located in California, the Redwood recycling facility in Nevada will support Toyota’s supply chain in North America.

This support will contribute to improving sustainability and facilitate operational enhancements across the company to establish a closed-loop battery system.

Related content: Toyota brings the 2025 Corolla Cross and Yaris Cross hybrids to Colombia

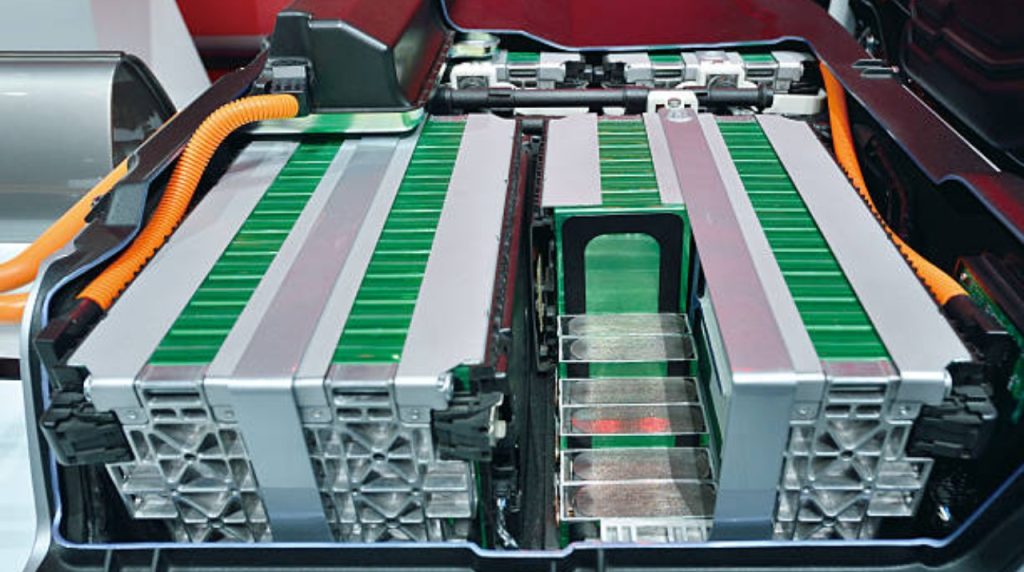

Toyota’s battery lifecycle system is projected to encompass recycling, remanufacturing, and reusing nearly five million operational units, advancing toward Toyota’s ultimate goals of achieving carbon neutrality in its global operations by 2035 and in its vehicles by 2050.

Measures taken by Toyota

One of the measures taken by Toyota to address the internal demand for battery recycling was partnering last year with Redwood Materials, establishing an expanded recycling agreement.

This was done with the purpose of charting pathways for the car batteries that have reached the end of their life in the brand’s electric vehicles.

Additionally, this plan includes an agreement for Toyota to acquire cathode active material and anode copper foil through Redwood’s recycling operations, destined for the future production of new batteries for the Asian brand’s vehicles.

Finally, by working with Redwood Materials, Toyota creates a circular supply chain to optimize logistics, expand refining, and ensure that valuable recovered metals can be reintroduced into their vehicles.