Battery Innovation Retains 98% of its Storage Capacity after 500 Charge Cycles

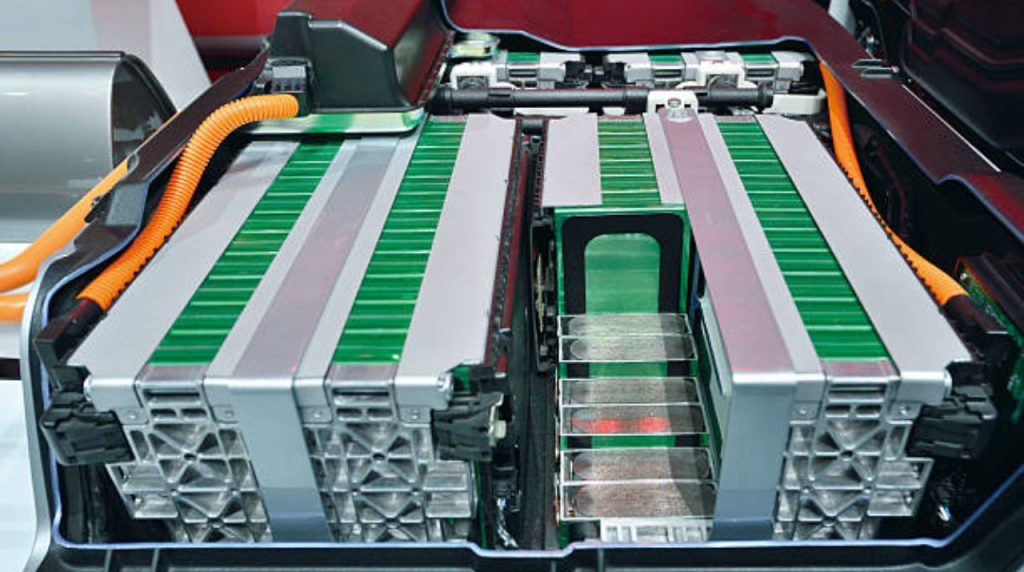

The Argonne National Laboratory in Illinois, USA, developed an advanced design for lithium-ion battery cathodes that optimizes performance, stability and reduces costs, promoting the adoption of electric vehicles and grid energy storage systems.

The design could accelerate the adoption of electric vehicles (EVs) and grid storage systems and is key to global decarbonization efforts.

In 2012, Argonne’s research team set a milestone in lithium-ion batteries by introducing a novel cathode material that significantly increased energy density and durability.

You may also read: General Motors Invests $10 Million for Battery Development

This breakthrough was made possible by adjusting the composition of nickel, manganese and cobalt in the cathode particles, successfully optimizing the properties of these metals.

Key Aspects

The key to the design lies in the “composition gradient” configuration, where the nickel concentration progressively decreases from the core to the particle surface.

This approach allows high energy density to be maintained for operations at high voltages, while minimizing reactivity.

This breakthrough has implications for the manufacture of more compact and economical batteries, benefiting the mass adoption of electric vehicles and grid storage systems.

The cathode particles in this design possess a layered structure, a common feature in today’s commercial batteries.

The ordered layers of metal atoms create channels that facilitate the transport of lithium ions between the electrodes, which is critical to the battery’s charging and discharging process.

For EVs to replace fossil fuel vehicles globally, batteries need to operate at higher voltages without compromising safety or durability.

High-voltage operations often induce cracks in the cathode particles and increase reactivity with the electrolyte, which degrades battery capacity and shortens battery life.

Argonne’s team solved this problem by introducing a “dual gradient” design in which the material structure gradually transitions from a disordered state at the surface to an ordered state in the core.