Study: European Union Works to Reduce Impact on Battery Manufacturing in Relation to China

A study carried out by T&E (Transport & Environment) shows a key opportunity to significantly reduce carbon emissions in the manufacturing of batteries for electric vehicles, where the relocation of the supply chain of these batteries to Europe is presented as a strategy to achieve this. aim.

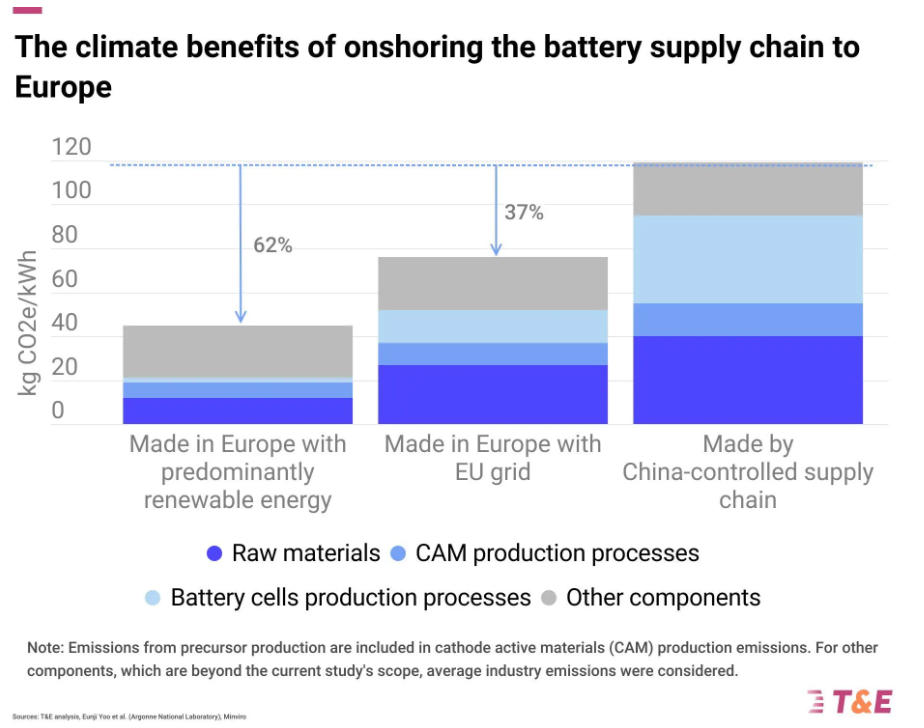

According to the report, this change could reduce carbon emissions by 37% compared to a supply chain dominated by China. One of the main factors behind this reduction is the difference in the carbon footprint of electricity production between Europe and China.

Europe is moving rapidly towards renewable energy sources, where the electricity used in battery manufacturing would be cleaner and less carbon-intensive. In fact, when renewable electricity is used in battery production, carbon savings skyrocket to more than 60%.

Related content: T&E: Battery Manufacturing in Europe Could Generate 60% Less Carbon than in China

Emissions reduction

This study provides evidence that localizing battery production in Europe can have a significant impact on reducing greenhouse gas emissions associated with electric mobility.

In addition to the environmental benefit, this measure could also have positive economic implications for Europe, encouraging job creation and the development of a competitive battery industry in the region.

“Batteries and the metals that make them up are the new black gold, the new goose that lays the golden eggs. European leaders will need sharp focus and shared thinking to reap both climate and industrial benefits,” said Carlos Rico, Transport and Environmental Policy expert at T&E.

“Rigorous sustainability requirements, such as upcoming battery carbon footprint regulations, can incentivize clean local production. Even more importantly, Europe needs better tools within the framework of the European Investment Bank and the Fund. of the EU for Batteries to support investments in gigafactories”, he concluded.